AccuThrive Blades: Redefining Surgical Precision

AccuThrive Blades are 28.5–50% sharper, 3.5x more durable and engineered for flawless incisions. Want to see how they redefine surgical precision? Here’s how.

In surgery, blade performance is not just about cutting—it is about outcomes.

Superior blades glide through tissue with minimal resistance, decreasing trauma and scarring, and promoting faster healing.

Top-quality blades also last longer, reducing intraoperative changeouts and operating room (OR) time.

For specialties where aesthetics matter—plastic surgery, dermatology, ophthalmology and otolaryngology—blade precision is paramount. Patients often judge surgical success by their incision’s appearance.

“A scalpel is one of the most important things to a surgeon who operates anywhere on the body—if we were samurai, this would be our sword,” says Dr. Joseph Niamtu, a cosmetic surgeon in Richmond, Virginia.

While blade cost is negligible compared to overall surgical expenses, the wrong blade can have costly consequences.

Why Blade Quality Matters

The difference between an ordinary blade and an exceptional one impacts:

Surgical Control & Precision

The sharpest scalpels cut through tissue with ease, giving a surgeon maximum control over the depth and direction of an incision. The sharpest and smoothest blades allow for clean incisions and minimize microscopic tears to patient tissue. A 2016 study in Dermatological Surgery found that dull blades increase shearing forces, causing greater tissue damage. i

Operational Efficiency

Inventory: Dull blades require higher stock levels. A 3.5x more durable blade (like AccuThrive’s) can slash inventory needs by two-thirds.

OR Time: Each blade change wastes ~20 seconds—precious time when the mean cost for one minute of OR time is $46.04 (including anesthesia) and space may be limited. ii

Sharps Injury: Each blade change risks a sharp injury. An estimated 385,000 hospital workers in the U.S. suffer a sharps injury each year and nearly half of the incidents take place in operating rooms. As of 2022, the average cost of a single sharps injury was estimated to be $4,352. iii iv v

Surgeon Fatigue

Dull blades demand excessive force, compounding physical strain. Nearly 70% of surgeons experience musculoskeletal pain, often linked to prolonged procedures. vi

Healing & Scarring

Rough incisions from dull blades increase wound size, inflammation and fibrosis. A 2020 study found that animal models that underwent nerve transection with a highly refined #15 blade (like AccuThrive’s) showed significantly faster axonal conduction recovery and an increased recovery of intra-axonal neurofilament compared to performing the same procedure using unpolished blades. vii Clean edges heal faster with less tension on sutures.

AccuThrive Blades: The Sharpest Choice

In head-to-head testing against leading #15 blades using a skin-mimicking (homogeneous) medium:

AccuThrive blades proved:

- 28.5–50% sharper than uncoated competitors viii

- Lowest cut force—requiring minimal pressure for smooth, precise incisions viii

- 3.5x more durable, reducing changeouts and inventory costs viii

“It is critical for us, as engineers, to get involved in the cutting process alongside our customers,” says Randy Herman, VP of Engineering at AccuTec. “By understanding their challenges firsthand, we can create blades that deliver optimal performance for their specific applications. We spend so much time doing our research and it helps us consistently put forth the best cutting solutions.”

Surgeons report immediate improvements: fewer blades per procedure, smoother incisions and superior patient outcomes.

“I have been using AccuThrive surgical blades regularly for almost a year and have found them to be significantly sharper than our previous blades,” says Raymond Dunn, MD, a plastic surgeon in Worcester, Massachusetts. “This enhanced sharpness has improved accuracy and precision in incisions, resulting in cleaner, more precise dermal margins. This facilitates better closure, promotes more favorable healing and

reduces scar formation. Additionally, the blades maintain their sharpness for much longer compared to our previous scalpel blades.”

Engineering Excellence: The AccuThrive Difference

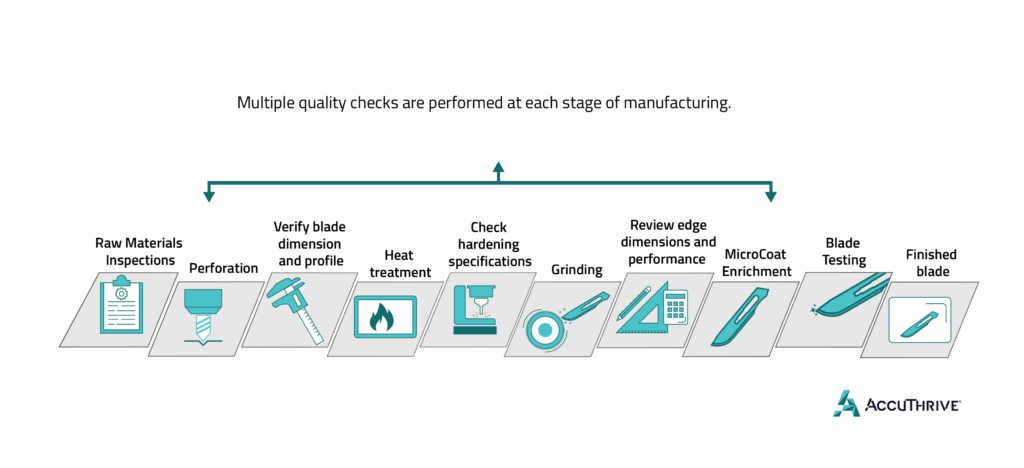

With 150 years of blade manufacturing experience, our process ensures perfection:

Premium Steel Selection

Corrosion-resistant, medical-grade steel with fine grains structure produces flawless edges. We start by sourcing the best corrosion-resistant medical grade steel. “You can only make finite edges with clean steel, otherwise there will be junk in the material that will end up at the blade edge and leave a void,” Herman says. “We want fine grain steel in the rolling process because that is what is going to end up on the blade edge and that’s how we can maintain high-quality edges.”

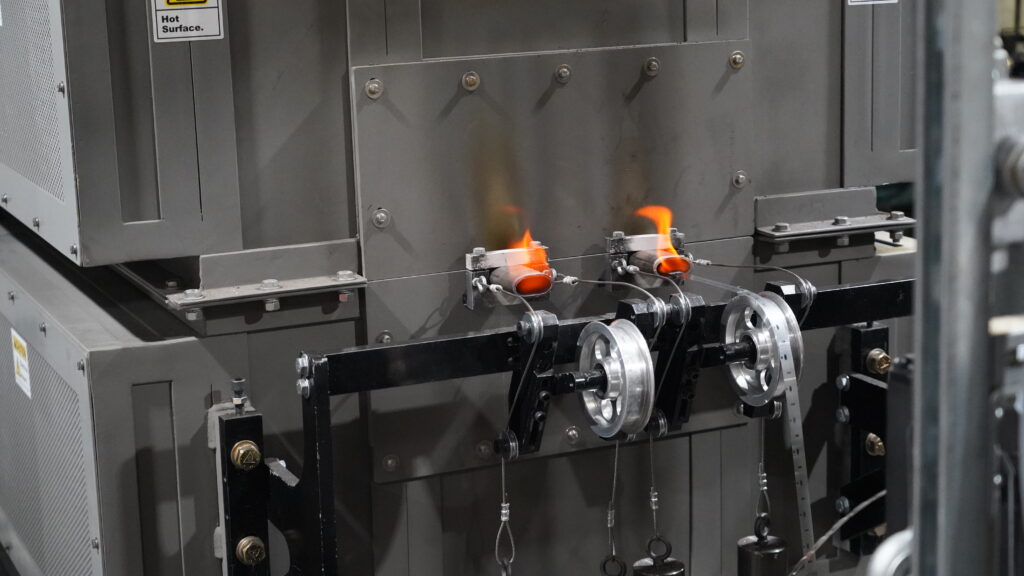

Precision Grinding

Custom, vibration-free grinders produce straighter, sharper edges than competitors. All along the production line, blades are tested and retested to meet precise internal standards. Controlled heating and cooling processes harden and improve steel properties. When the blades reach the grinders, that’s where tip geometry begins to take shape.

“The fact that our grinders are all custom and very massive means that we can eliminate nearly all of the vibration, allowing us to create perfectly straight edges,” Herman says. “A lot of our competitors can’t do that.”

Proprietary ‘Stroning’

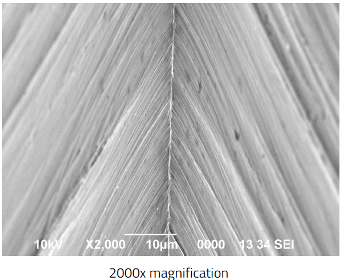

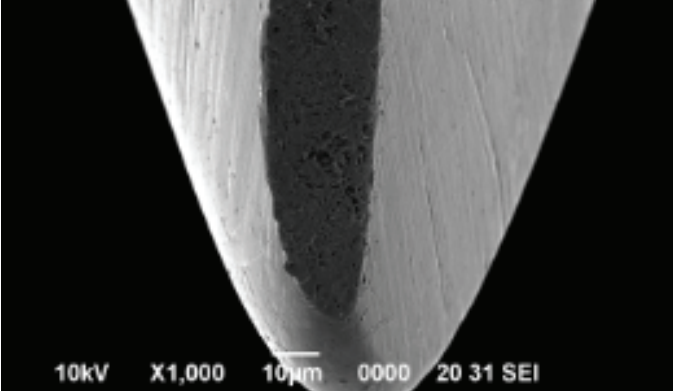

After grinding, most manufacturers perform two additional processes—honing, to realign and slightly sharpen the edge, and stropping, to remove microscopic imperfections and polish the blade for maximum shine. “The intricacies of our honing wheels are different than everyone else,” says Micah Herron, director of engineering. “We’ve developed a proprietary ‘stroning’ process, a honing and stropping process all in one, so we produce a highly-refined, clean edge for surgeons. When you look at our blades under a scanning electron microscope, zoomed in to 1,000 or 2000x magnification, as in Figure 1, you see a perfect edge, There are absolutely no abnormalities in our blade edge.”

Figure 1

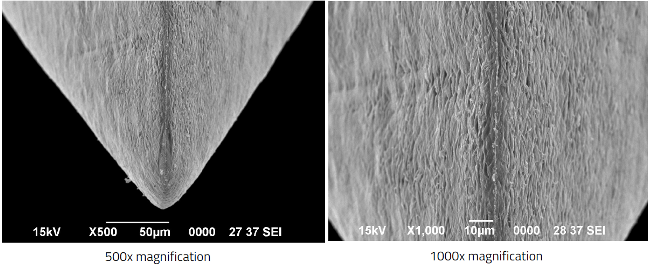

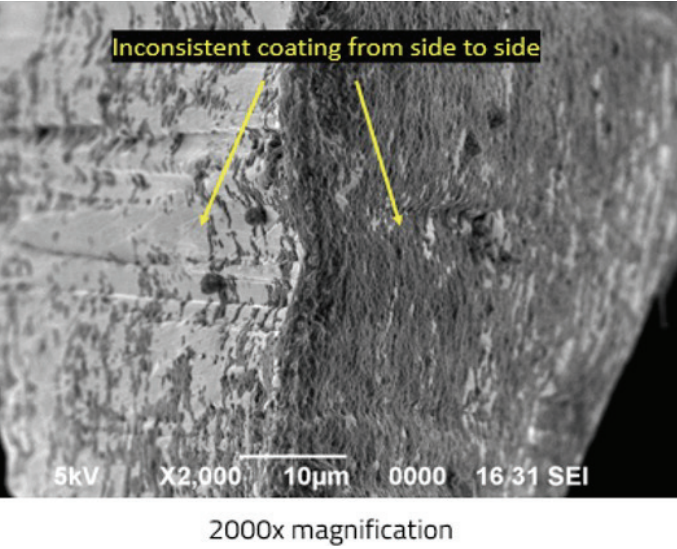

Proprietary MicroCoat® Technology

Very thin surface coatings increase wear resistance and reduce friction at the tip. We apply a multilayer coating to our surgical blade edges which controls blade edge sharpness from one end to the other, limiting tissue drag. When you look at Figure 2, you see a uniform layer of coating, not patchy spots.

Figure 2

Where Competitors Fall Short

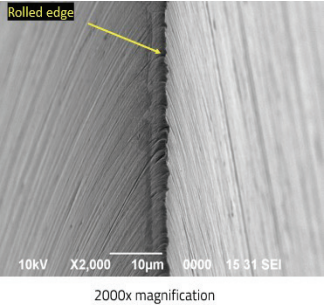

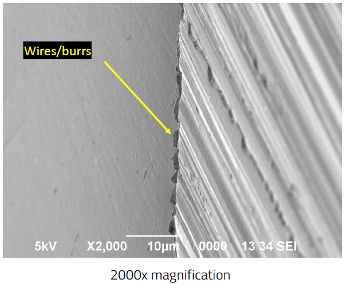

Microscopic defects in traditional blades undermine performance. Here are some examples of blade edges from leading competitors being used in hospitals today.

Figure 3: Uneven grinding creates a dull, rolled edge, increasing cut force and reducing longevity. This scanning electron microscope (SEM) image depicts the bevel edge of a competitor’s surgical blade. The dark stripe in the middle reflects post-production electromechanical grinding to remove small amounts of metal from the blade’s edge. However, imbalanced grinding wheels have resulted in inconsistent grinding, highly polishing one side but leaving a rolled, duller blade edge. This means a surgeon will have to apply more force to puncture a patient’s skin and create an incision. The blade will also dull more quickly.

Figure 4: Debris on grinding wheels leads to inconsistent sharpness. This SEM image shows a competitor’s uneven blade edge, likely the result of failing to remove debris and buildup from the grinding wheels prior to shaping and sharpening the steel. This creates an uneven grinding surface, which ends up removing more material in some areas than others.

Figure 5: Wires and burrs are caused by improper grinding and are seen as sharp, raised edges on the blade tip. These cause the scalpel to drag on tissue and dull more quickly.

Figure 6: Patchy coating causes erratic sharpness and durability. At 2000x magnification, this SEM image shows a heavy coating on the right side, while the coating on the left side is sparse. Uneven and inconsistent coating can lead to inconsistency in blade sharpness and durability. Uniform coating leads to consistent performance.

AccuThrive Blades: Sharper, Smoother, Longer-lasting

From steel selection to final polish, every AccuThrive blade is engineered for smoothness and peak performance. For surgeons who demand the best and want better outcomes and lower costs, the choice is clear.

Feel the AccuThrive difference for yourself.

To request a blade sample or trial, email info@accuthrive.com

I Awadalla F, Hexsel C, Goldberg LH. The Sharpness of Blades Used in Dermatologic Surgery. Dermatol Surg. 2016 Jan;42(1):105-7. doi: 10.1097/DSS.0000000000000584. PMID:26655703.

II Smith, T. ., Evans, J. ., Moriel , K. ., Tihista, M., Bacak, C. ., Dunn , J. ., Rajani , R. ., & Childs, B. (2022). The Cost of OR Time is $46.04 per Minute . Journal of Orthopaedic Business, 2(4), 10–13.

III https://www.cdc.gov/infection-control/hcp/sharps-safety/index.html

IV https://www.aorn.org/outpatient-surgery/article/2022-May-sharps-playbook

V https://www.danielshealth.com/faq/what-average-cost-needlestick-injury#:~:text=In%20 the%20US%20as%20of,or%20litigation%20and%20compensation%20costs.

VI Wells, A.C., Kjellman, M., Harper, S.J.F. et al. Operating hurts: a study of EAES surgeons. Surg Endosc 33,933–940 (2019).

VII Prescher H, Ling MX, Bigdelle V, Spiro CL, Lee RC. Scalpel edge roughness affects post- transection peripheral nerve regeneration. Surg Open Sci. 2020 Nov 18;4:1-6. doi: 10.1016/j.sopen.2020.11.002.PMID: 33537665; PMCID:PMC7838729.

VIII Internal testing report, 15 Surgical Blade Comparison, 1/24/2025

READY TO PLACE AN ORDER?

Let’s Connect

Join our mailing list to receive email updates on new product announcements, clinical articles and trade shows where you can test AccuThrive blades.